A powerful industrial network to match your ambitions

At Colissimo, we know that a successful delivery starts with solid, smooth and reliable logistics. Delivering quickly, efficiently, and everywhere: this is the promise you make to your customers. And it is the promise we help you keep.

That is why we have built an industrial network designed to meet the demands of modern e-commerce: speed, precision, agility, sustainability. Every day, our platforms, hubs and distribution sites coordinate thousands of flows to deliver your customers wherever they are — in mainland France, the Overseas territories, or internationally.

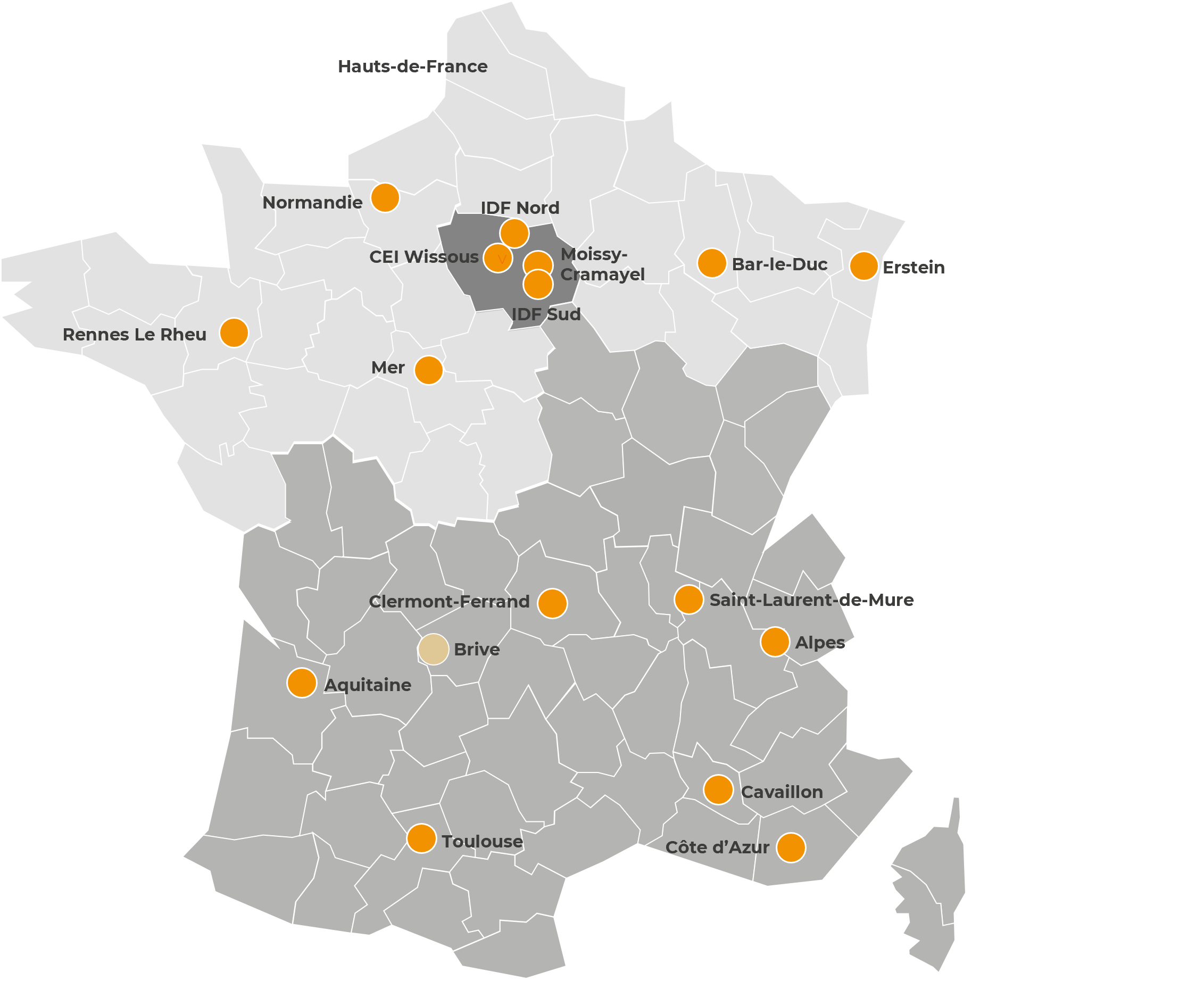

Industrial and logistics innovation serving responsible and competitive delivery across our 18 platforms and hubs

To support the growth of e-commerce, Colissimo continuously develops its industrial network.

Our goal: to offer reliable, accessible and responsible delivery solutions that meet the expectations of e-retailers and their customers.

We invest regularly to maintain a logistics infrastructure capable of ensuring the same high level of performance all year round, including during peak periods.

Our facilities integrate the latest technological innovations to optimise flows, speed up lead times, and ensure a consistent quality of service.

Our network today relies on 18 parcel platforms and hubs, located in strategic areas, along with numerous distribution sites, ensuring a dense and responsive coverage at national level to deliver mainland France, the Overseas territories and international destinations.

Cutting-edge innovation powering our platforms

The new industrial sites integrate cutting-edge equipment, specially designed for La Poste’s needs, to strengthen logistics performance while improving daily working conditions for teams.

Several of these innovations are based on controlled and ethical use of artificial intelligence, to streamline parcel processing, shorten delivery times, and ensure reliability at every stage of the logistics chain.

Loading and unloading bays have been increased in number and optimised in layout to streamline flows and reduce the risk of accidents.

Our new-generation platforms are equipped with dual sorters capable of handling up to 40,000 parcels per hour.

A technology that creates a shortcut for parcels on the sorting carousels to reach their loading bay and departure point even faster.

Automatic scanning capable of reading all six sides of a parcel to capture label information and direct it towards the right destination.

A system of spiral chutes to guide parcels from the sorter down to the loading bay, preserving their integrity.

Articulated unloading arms called “Express snoots” reduce twisting movements and the manual handling of parcels by teams.

The automation of light, sometimes unstable small parcels on carousels allows autonomous processing of up to 29,000 parcels per day.

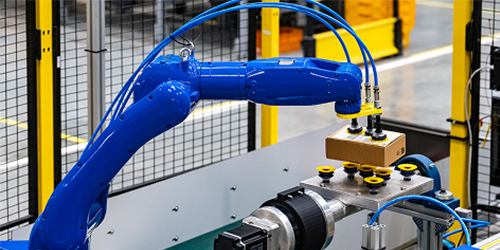

Robotic arms connected to autonomous robots improve working conditions for teams while optimising the processing of small parcels.